Welcome to Leahy-Wolf Lubricants, the premier Heavy Industrial Fluid distributor in the Great Lakes Region. With over 75 years of experience in the industry, we have established ourselves as the go-to supplier for top-quality lubricants that keep heavy machinery running smoothly and efficiently. Our comprehensive product line includes a vast range of greases, fire-resistant hydraulic fluids, gear oils, and compressor fluids, ensuring that we have the right solution for your specific needs.

We are proud of our commitment to customer service, and we have assembled a seasoned sales staff to provide personalized solutions to meet your unique requirements. Our sales team is led by Jim Mack and Scott Bachert, two industry veterans who bring a wealth of knowledge and expertise to every situation. Scott is primarily focused on steel production, with a deep understanding of the challenges and demands of the industry. Meanwhile, Jim’s expertise is in steel processing, ensuring that we can offer tailored solutions to meet the needs of every customer, regardless of their area of operation.

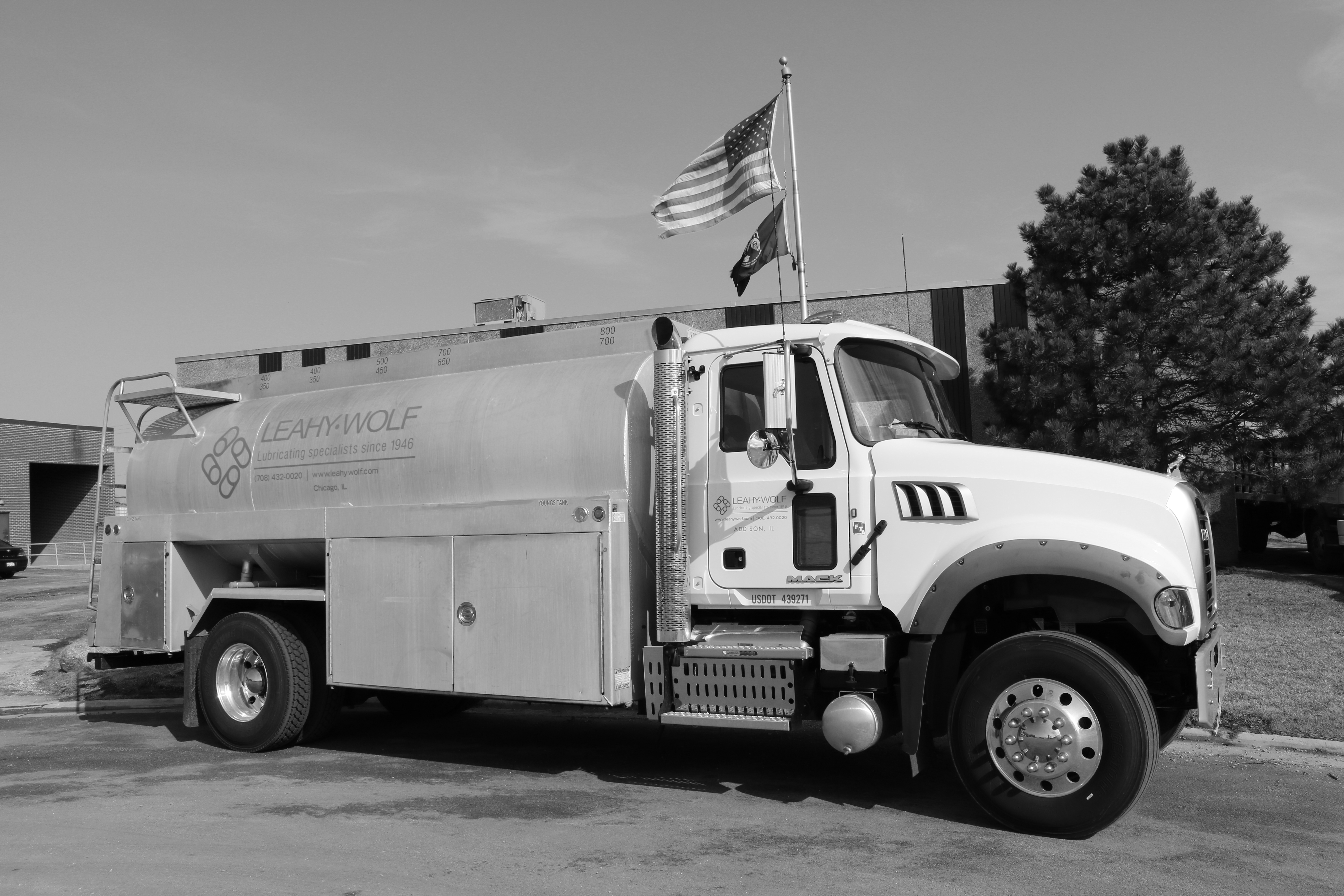

One additional thing that sets Leahy-Wolf Lubricants apart from other distributors is our logistics capabilities. We operate our own fleet of trucks, manned by a team of experienced drivers who know how to navigate industrial sites safely and efficiently.

KEY PRODUCTS

HEAVY DUTY GREASES

The PEERLESS family of greases are premium performance, multi-application greases formulated to reduce operating costs and provide extended protection in extreme high temperatures or wet operating conditions.

FIRE RESISTANT HYDRAULIC FLUID

Hydraulic fluids such as water-based water glycol and full synthetic polyalkylene glycol (PAG) are used in high temperature applications and in situations where standard mineral oils could catch fire. PAGs have several advantages over other hydraulic fluids, including high temperature stability (resistance to thermal degradation), hydrolytic stability (resistance to breaking down in the presence of water), superior lubrication (reducing friction and extending component life), oxidation stability (low molecular polar by-products that do not form sludge or varnish), high viscosity index (maintaining consistent viscosity over a wide temperature range), compatibility with commonly used elastomers (gaskets, seals, and hoses), and Factory Mutual approval (meeting insurance requirements).

COMPRESSOR FLUIDS

COMPRO Compressor fluids provide long and reliable service life in industrial air compressor applications. The COMPRO line of products provides excellent oxidative stability and strong resistance to sludge and varnish formation, while reducing overall compressor maintenance costs.

GEAR OILS

Petro-Canada provides a complete line of lubricants for gear drives and bearing systems operating under the toughest conditions — whether under extreme pressure or wide ranges of temperature.

KEY SERVICE CAPABILITIES

Leahy-Wolf Lubricants is able to service the northwest Indiana area from two convenient locations, one in Addison, IL and one in Porter, IN. With a fleet of 13 delivery trucks, Leahy-Wolf is able to reach customers in a timely manner and provide the necessary lubricants and fluids. Each truck is equipped with four segregated pumps and meters, allowing for the proper handling and delivery of different types of fluids. By having multiple locations and a reliable fleet of delivery trucks, Leahy-Wolf is able to meet the needs of its customers in northwest Indiana and beyond.

OIL CONDITION MONITORING & ANALYSIS

Lubricant testing and analysis is a crucial aspect of maintaining and improving the performance of machinery and equipment. By regularly testing and analyzing lubricants, it is possible to identify any problems or potential issues that may be impacting the efficiency of the equipment. For example, lubricant testing can help to identify contaminants that may be present in the lubricant, as well as measure the wear of the lubricant and assess its overall condition. This information can be used to optimize the lubrication program, extend the life of the equipment, and improve overall performance. Additionally, lubricant testing and analysis can be used to verify that the lubricant meets the necessary specifications and requirements for a particular application. Overall, lubricant testing and analysis is an important tool for ensuring that machinery and equipment are operating at their best.