The range of temperatures, the volatility of working conditions, the seasonality of work coupled with intense capital investments and increasing labor costs require lubricants that perform and provide long-lasting life to the high-cost construction business.

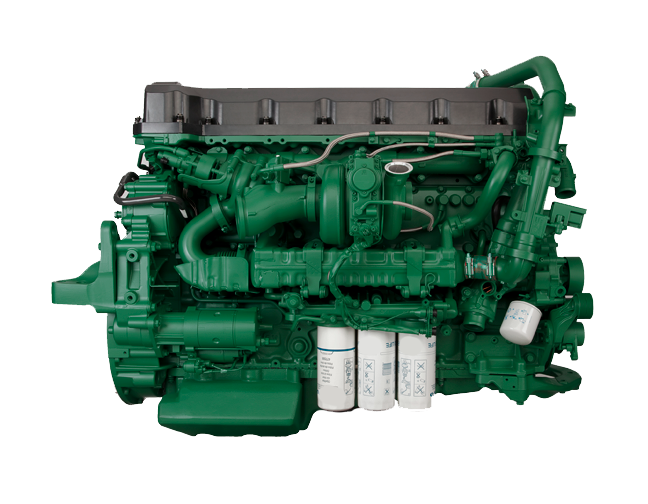

DIESEL CRANKCASE OIL

CONVENTIONAL

Standard conventional diesel engine oils will remain the work horse of the industry for the next few years. As current older fleets are replaced with more efficient power units, this weight class will steadily lose market share.

Common weight 15W-40

API Service Category CK-4

SYNTHETIC BLEND

Blended synthetic diesel engine oils were designed for fuel economy. The EPA has mandated that engine manufacturers meet increasingly stringent fuel economy standards. A reduction in engine oil viscosities is the only way these standards can be met. Diesel engine oil viscosities will surely become lighter over time.

Common weights 15W-40/10W-30

API Service Category CK-4

FULLY SYNTHETIC

Fully synthetic diesel engine oils were designed for cold weather and extended drain intervals. Highly refined lower viscosity base oils increase pumpability while more robust VI improvers allow the fluid to stay in grade over a wider temperature range.

Common weights 10W-40/5W-40/0W-40/5W-30

API Service Category CK-4 & FA-4

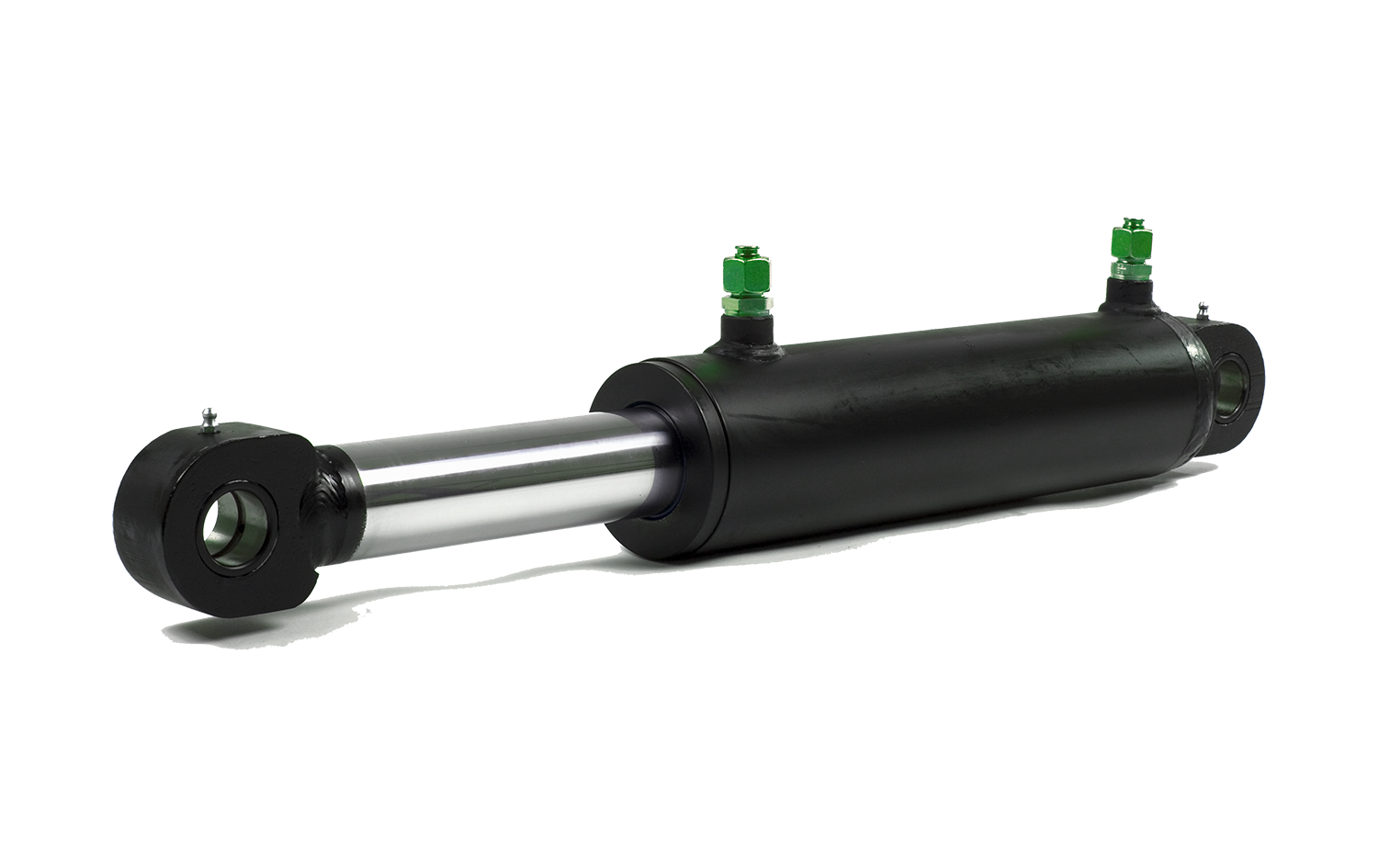

HYDRAULIC FLUID

ANTI-WEAR

These monograde hydraulic oils are designed for high-performance anti-wear protection and long life in moderate outdoor climates or for indoor use. These lubricants contain no viscosity index improver so they thin out as they heat up.

Common weights: AW-22/32/46/68

MULTI-VISCOSITY

Multi-Viscosity hydraulic oils are designed for heavy duty applications operating at high pressures in a wide temperature range. MV fluids are similar to anti-wear hydraulic oils but they include a viscosity index improver. This VI improver is a plastic polymer which expands as the temperature increases. This expansion happens at about the same rate as the base oil thins maintaining the same viscosity over a wide temperature band.

Common weights: MV-22-32-46-68

ENVIRONMENTALLY SAFE

Environ fluids are designed for use in equipment used primarily in environmentally sensitive areas. It is free of heavy metals (zinc), is non-toxic, inherently biodegradable, and recyclable. It comes in Anti-Wear as well as Mulit-Viscosity versions.

Common weights: AW-32/46/68 MV-32/46

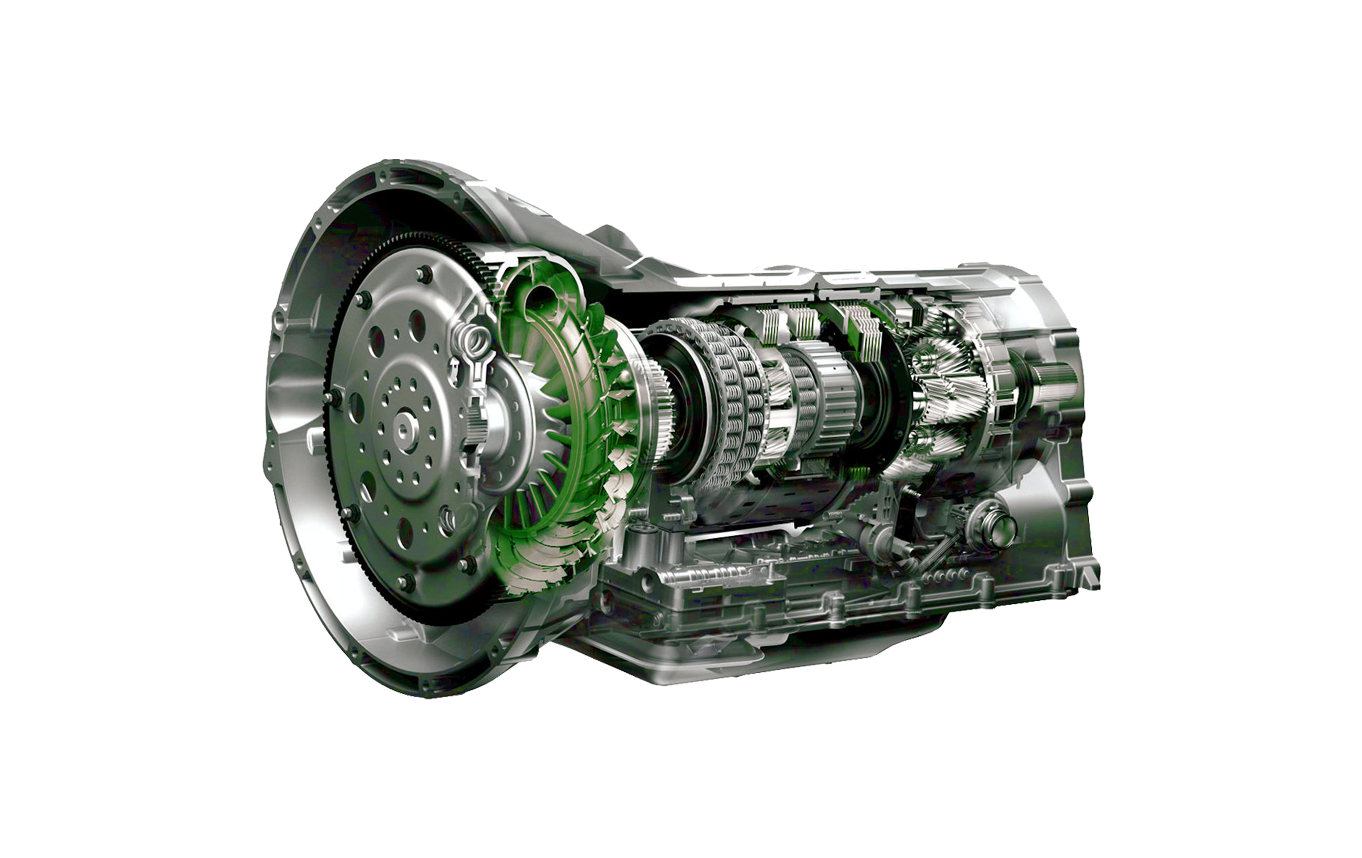

TRANSMISSION FLUID

SYNTHETIC AUTOMATIC

This oil has become the most common multi-grade automatic transmission fluid and gear oil in the transportation industry here in the Chicago area. It’s synthetic base oil and extreme pressure additive package allow for greater wear protection at cold temperatures and better thermal stability at higher temperatures.

Common weights: 75W-90/80W-140

SYNTHETIC MANUAL

Heavy Duty Synthetic Transmission Fluid is selectively engineered for heavy duty manual transmissions operating in severe service applications.

Common weight SAE-50

HYDROSTATIC TRANSMISSION

Hydrostatic transmission fluid is designed for construction equipment with a common oil system for transmission, differential, hydraulic, power take-off, wet brake and power steering mechanisms. These fluids are heavily additized and contain a viscosity index improver.

These fluids are commonly SAE 10W-30

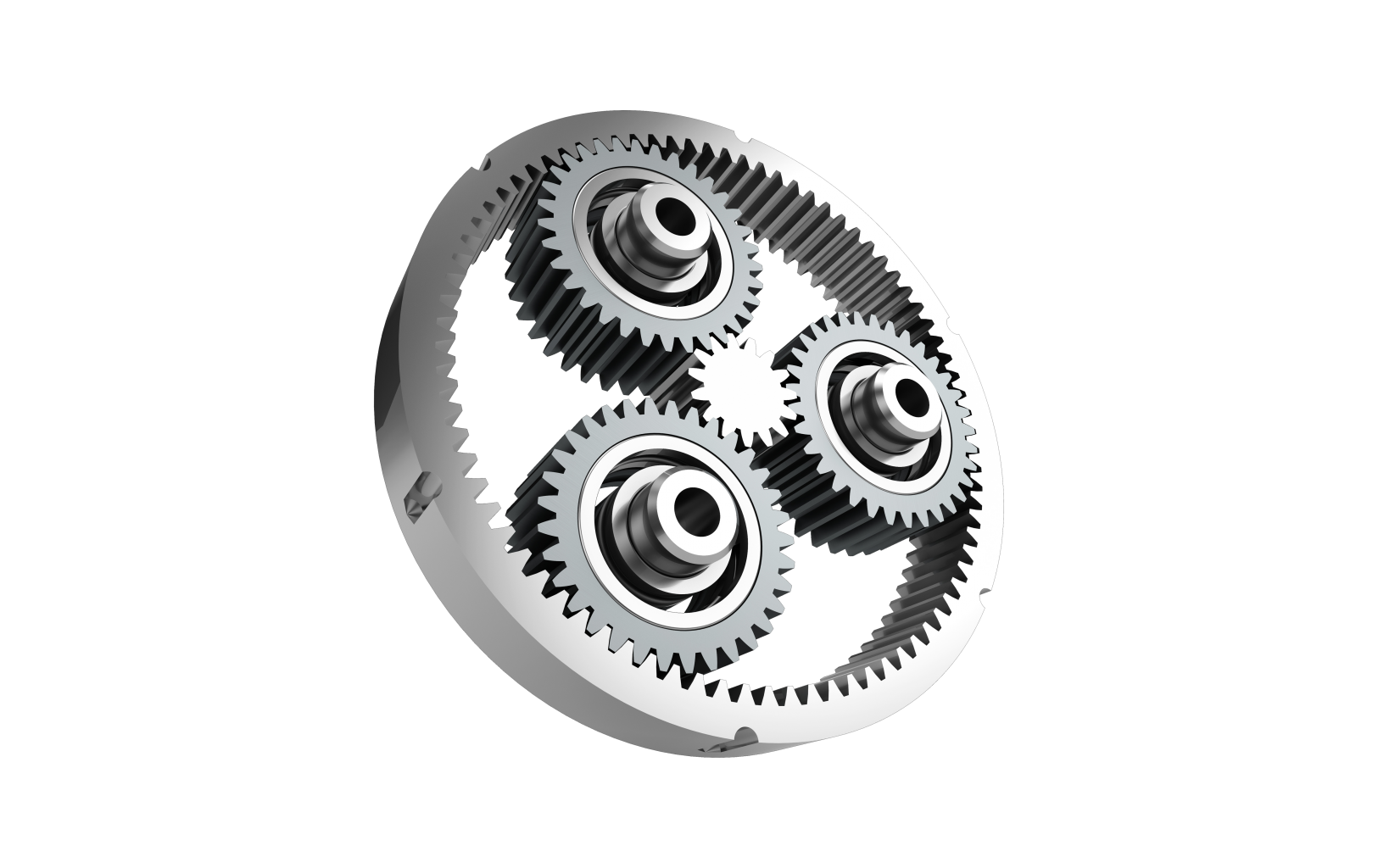

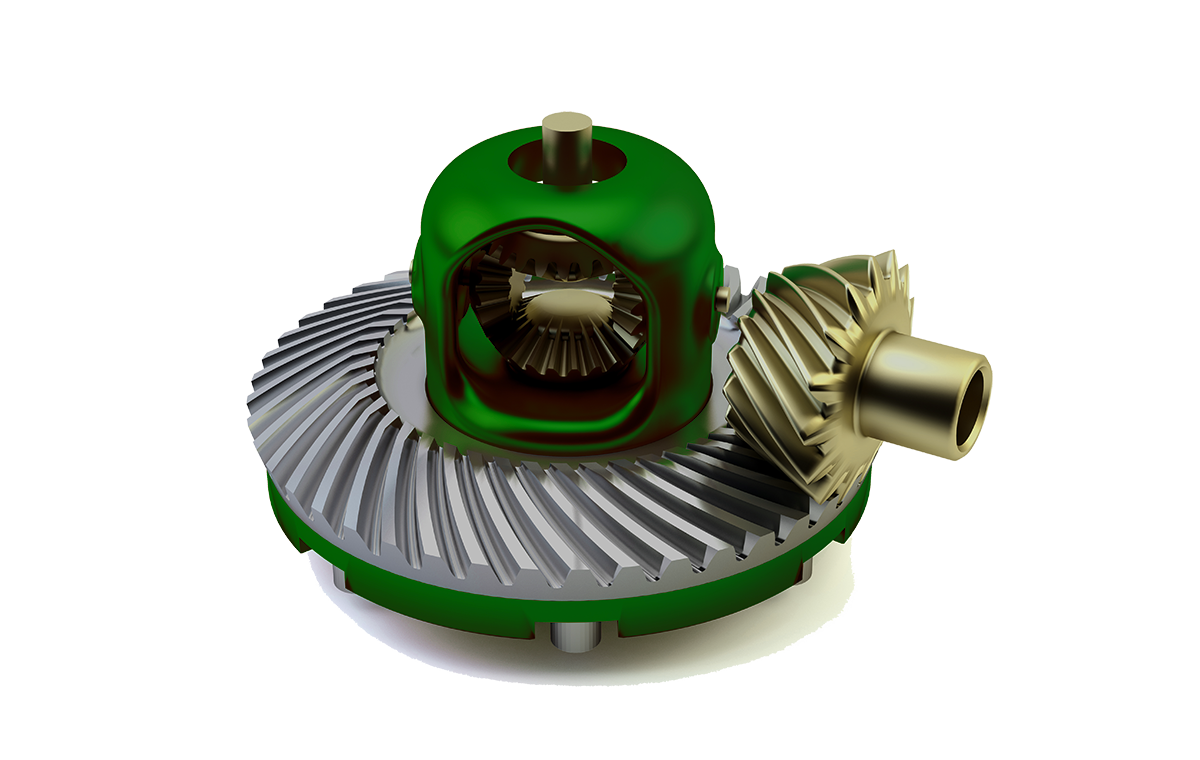

DRIVE TRAIN FLUID

TDTO (Transmission Drive Train Oil)

These fluids are designed to meet and exceed Caterpillar TO-4 lubricant specifications. They provide excellent protection, long oil life, smooth operation and lower operational costs. They also maximize the life of frictional materials in Caterpillar powershift transmissions, minimize wet brake chatter, and provide excellent anti-wear protection for hydraulic pumps, transmissions, & final drives.

Common weights: 10W/30/50/60 (30, 50, & 60 are multi-grades)

GEAR OIL

CONVENTIONAL

In cold weather environments like Chicago, this class of fluids makes up less than 20% of the gear oil market. Regional fleets in warmer climates may still use this type of fluid.

Common Weight 80W-90

SYNTHETIC

In recent years, the majority of fleets and repair facilities have moved to fully synthetic differential oils. These multi-grade oils are manufactured with a lighter base oil for better cold weather protection and a more advanced extreme pressure additive package. They also have a recommend service life of 250,000 miles.

Common Weight 75W-90

TRAXON E SYNTHETIC MTF

MTF is recommended for extended drain and severe service in heavy duty (class 6, 7, and 8) manual transmissions requiring a non-EP lubricant. MTF is backward serviceable to Eaton PS-164 Rev 7. This product meets or exceeds the performance requirements for:

- API MT-1

- Eaton PS-386

- Approved for use in Eaton transmissions such as UltraShift Plus, Fuller Advantage Series (FAS), FR and RT Series

- Extended warranty coverage at Eaton Corporation (500,000 miles)

- Mack TO-A PLUS

- International TMS 6816 / Navistar MPAPS B-6816 Type II

GREASE

GENERAL

Greases are made of heavy base oils of varying viscosities combined with application specific thickeners sometimes referred to as soaps and extreme pressure additives.

THICKENERS

Soaps are the most common emulsifying agent used, and the selection of the type of soap is determined by the application. Soaps include calcium stearate, sodium stearate, lithium stearate, as well as mixtures of these components. Fatty acids derivatives other than stearates are also used, especially lithium 12-hydroxystearate. The nature of the soaps influences the temperature resistance (relating to the viscosity), water resistance, and chemical stability of the resulting grease.

ADDITIVES

Some greases are labeled “EP”, which indicates “extreme pressure”. Under high pressure or shock loading, normal grease can be compressed to the extent that the greased parts come into physical contact, causing friction and wear. EP grease contains solid lubricants, usually graphite, and/or molybdenum disulfide, to provide protection under heavy load. The solid lubricants bond to the surface of the metal, and prevent metal-to-metal contact and the resulting friction and wear when the lubricant film gets too thin. Some greases specify the percentage of Molybdenum disulfide or “Moly” is an indication of shock loading capability.

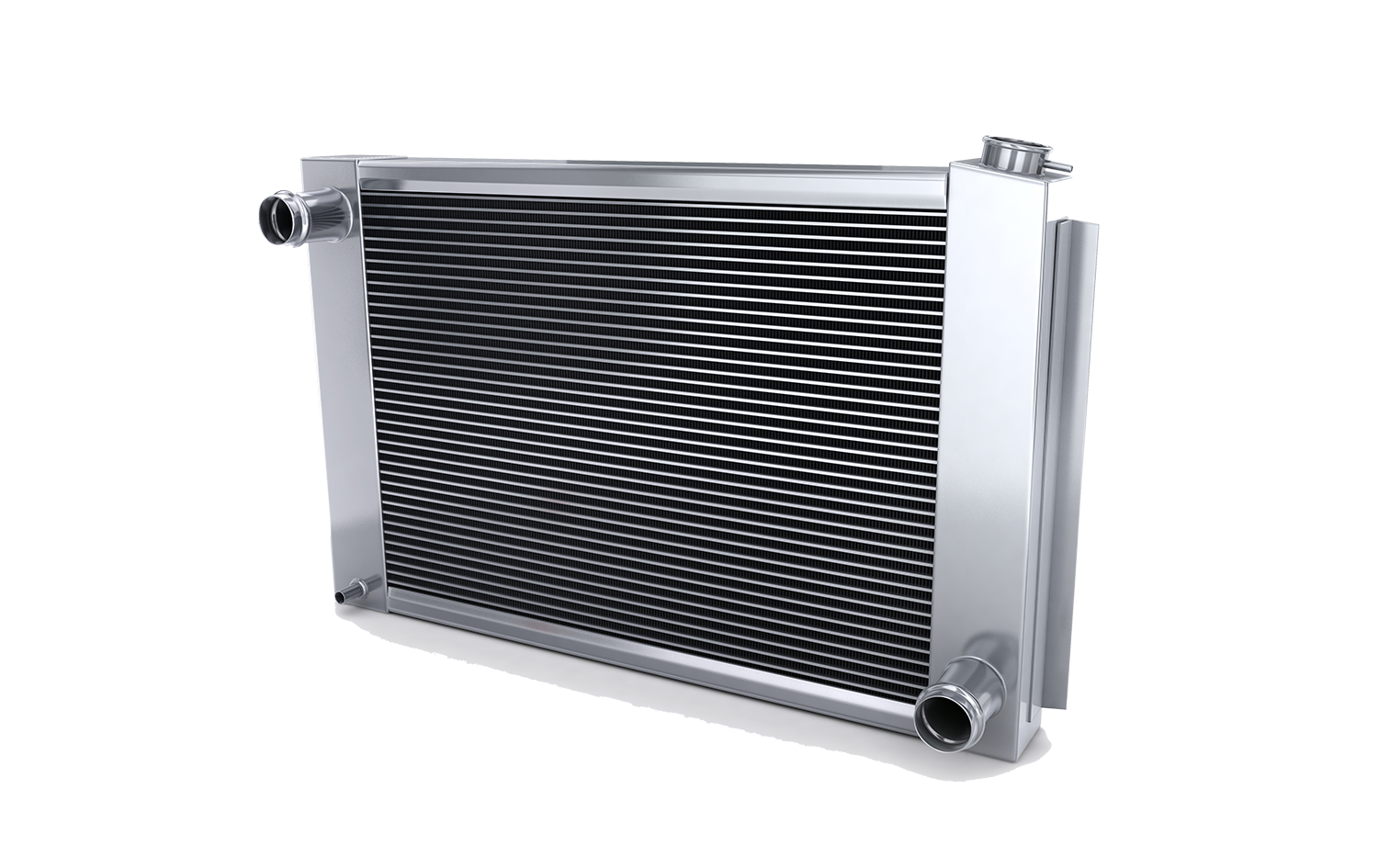

ZEREX ANTIFREEZE

EXTENDED LIFE DIESEL COOLANTS

ZEREX™ Extended Life Antifreeze/Coolant patented formula has been charged with special inhibitors to protect diesel engines from liner pitting and hard water scale deposits for longer engine life. With the addition of an extender product, you can go 6 years, 14,000 hours, or 600,000 miles without changing your antifreeze. ZEREX Extended Life Antifreeze/Coolant uses the highest quality virgin ethylene glycol for freeze and boilover protection, and a patented hybrid organic acid (HOAT) corrosion inhibitor package to protect cylinder liners from cavitation and liner pitting and your engine from rust and corrosion. HOAT coolants typically mix an OAT with a traditional inhibitor, such as silicates or phosphates.

Proud Members: